Homepage Review

Environmental Impact

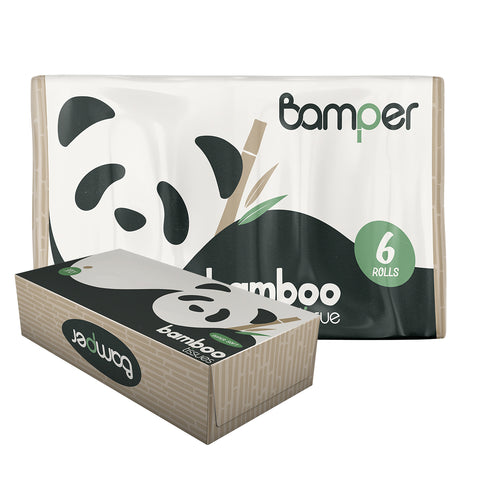

Every day, 27,000 trees are cut down just to make regular toilet paper. We believe making toilet paper out of bamboo is the best environmentally positive swap for regular toilet paper. You might be surprised to learn that bamboo is grass, not a tree. It grows incredibly quickly, making it a sustainable source for toilet paper. Buying Bamper 100% bamboo toilet paper will make you feel good knowing that you’re helping to reduce deforestation one flush at a time.

Frequently Asked Question

Write a complete answer to the most frequent questions that your customers might have, such as important product information, shipping policies, payment issues or returns.

Works well with most septic tanks: Bamboo toilet paper is unlike traditional toilet paper (and even recycled toilet paper) which tends to clog pipes and septic systems. Traditional toilet paper causes such trouble because it often does not fully break down. Bamboo toilet paper on the other hand is 100% biodegradable which leaves plumbing working well.

Our Bamper range is responsibly made in China. We understand this might be of concern to some, especially during a time where countries across the world are facing challenges around how best to support people, economies and our planet during a period of uncertainty. Whilst most of the products we consume here in Australia are made overseas, there’s a growing desire to support locally made.

As an Australian owned and operated business, we understand the importance of supporting each other, however, unfortunately it isn’t always that simple. At Urban Ethos we pride ourselves in being transparent about our ingredients, certifications, and manufacturing processes, as it is our number one priority to continue with our goal of positively impacting our planet throughout the journey. As a company, we will always provide you with all the necessary product information for you to make an informed choice to do what is best for your home, family and our planet.

Why is Bamper made in China?

When launching Bamper, the team looked at all viable manufacturing options and it was important to find a solution with the lowest possible environmental impact.

Below are the reasons why we ended up manufacturing Bamper in China:

- Firstly, bamboo is not harvested in Australia to produce paper pulp in commercial quantities, therefore, we needed to look outside Australia to find a suitable production source.

- Our manufacturing partners grow and manage their own bamboo forests which don’t disrupt any native habitats. They process their own paper pulp and manufacture the finished goods all in the same location. They do not rely on importing any raw material from other countries or locations, therefore keeping their carbon footprint as low as possible.

- We wanted our packaging to be plastic-free, our products to have no chemicals or artificial scents or dyes, and our manufacturing partner was very pleased to accommodate all our un-compromising environmentally responsible requirements.

The above factors allow us to have the lowest environmental impact and continue to have a positive effect on our planet, whilst delivering a quality product that is affordable and great to use.

What about working conditions?

Our manufacturing partner also meets many globally recognised certification standards, meaning they are independently audited. This includes all elements of their business: workers’ rights, freedom of association and collective bargaining, no discrimination, no child labour, no precarious employment, no bonded labour, and overall ethical business behaviours.

It’s important to our team and company ethics that each of our manufacturing partners across the world share the same vision – positive environmental impacts, integrity and operating with high moral standards.

Our manufacturing partner’s certifications:

The FSC certification is considered the "gold standard" designation for wood harvested from forests that are responsibly managed, socially beneficial, environmentally conscious, and economically viable.

ISO-9001 Certified

ISO 9001 is defined as the international standard that specifies requirements for a quality management system. Organizations use the standard to demonstrate their ability to consistently provide products and services that meet customer and regulatory requirements.

ISO-14001 Certified

ISO 14001 is the international standard that specifies requirements for an effective environmental management system.

What about the environmental impact of shipping products from overseas?

The production of toilet paper makes up most of the carbon footprint and the best action is to make the switch to Bamboo toilet paper (and tissues). We only transport our Bamper products by sea freight from the factory to our warehouse in Melbourne, as this is the most economical use of resources with the lowest possible carbon footprint.

Every day, 27,000 trees are cut down just to make regular toilet paper, and 140 litres of water is used per roll. Numerous chemicals are involved in the manufacturing process, including chlorine bleach to whiten the paper and artificial scents to add fragrance into the paper. We believe making toilet paper from 100% bamboo is the best environmentally positive swap for regular toilet paper. ZERO trees are affected, and you might be surprised to learn that bamboo is a grass, not a tree - it grows incredibly quickly, requires no chemical fertilisers and no harmful farming practices making it a sustainable source for toilet paper.

Buying Bamper 100% bamboo premium toilet paper will make you feel good knowing that you’re helping to reduce deforestation one flush at a time.

Each question asked are important and valid, so thank you for taking the time to ask them. We hope the above information has been helpful in making an informed choice about our Bamper range.